From high-end consumer electronics to mission-critical defense systems, increasingly complex designs can be difficult and costly to test. While it may be tempting to scale back on testing, a lapse in quality can lead to product failures and undesirable consequences–including less profit.

As the old saying goes, an ounce of prevention is worth a pound of cure. To understand how our customers are coping with these challenges, we at Keysight Technologies commissioned a survey by Dimensional Research, an independent technology market research firm. Our primary goal was to identify the issues that are undermining quality in the manufacturing of electronic devices.

Quality isn’t Easy

In total, 306 individuals across five continents participated in the survey. All were senior quality professionals who test electronic devices and designs.

Many of their responses were quite striking. For example, 64 percent confirmed that it has become more difficult to ensure product quality. They highlighted four key issues: increasingly lofty end-customer requirements; greater design complexity; the rising volume and pace of production; and tighter testing tolerances (e.g., due to stringent industry standards).

Effective quality control (QC) depends on reliable data, and accurate measurements are essential to valid go/no-go decisions in manufacturing. Among survey respondents, 92 percent said they have suffered negative business effects due to erroneous results from their test equipment. While some errors may be due to faulty measurement hardware, the more likely culprit is an instrument that is overdue for calibration.

Flawed Test Results are Costly

When test equipment is out of calibration, inaccurate readings can lead to “false pass” or “false fail” results on the production line. Reworking false-fail units adds labor cost, scrap cost, or both. Sending false-pass products into the marketplace can adversely affect customer satisfaction (intangible) and warranty costs (tangible). Worse yet, defective products might harm end users, potentially necessitating a recall and doing lasting harm to a company’s brand.

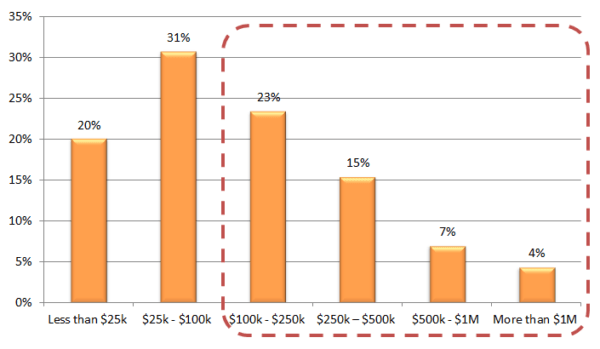

Either type of “false” result contributes to reduced output from the production process. Survey respondents were asked to estimate the cost of a one-percent decrease in yield. As shown in Figure 1, 49 percent believe they lose $100,000 or more for every one-percent drop.

Calibration has Multiple Benefits

The desired test outcomes are “true pass” and “true fail.” Ensuring the veracity of measurement results depends on the accuracy and repeatability of the instruments in every test system.

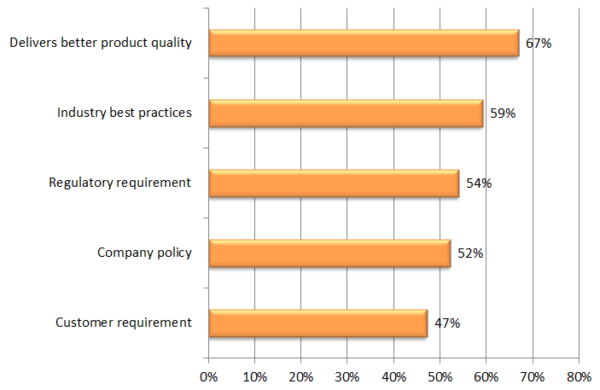

In this vein, the survey asked, “Why is it important for your company to have test and measurement equipment calibrated?” Figure 2 summarizes the answers.

Three of the five responses show the power of external drivers: “regulatory requirement,” “customer requirement” and “industry best practice.” However, the top response, at 67 percent, reflects a combination of internal and external imperatives: “delivers better product quality.” This outcome is in the best interests of the manufacturer and its customers.

The Bottom Line Will Thank You

In those industries that feel intense pressure on costs and prices, product testing and equipment calibration may slip under the dark veil of “necessary evil.” However, when testing and calibration are curtailed, the result is often an intertwined decline of quality, yield and customer satisfaction.

The results of the Keysight survey point to the bottom-line value of instrument calibration. Looking to the future, the emerging need is for system-level calibration of the entire measurement solution. This is the only way to account for cumulative inaccuracies in the multi-instrument measurements that are becoming more common with highly complex designs.

- How Digital Twins Can Accelerate New Innovation Adoption - June 18, 2022

- How Much Does a One-percent Drop in Yield Affect Your Profits? - December 3, 2019