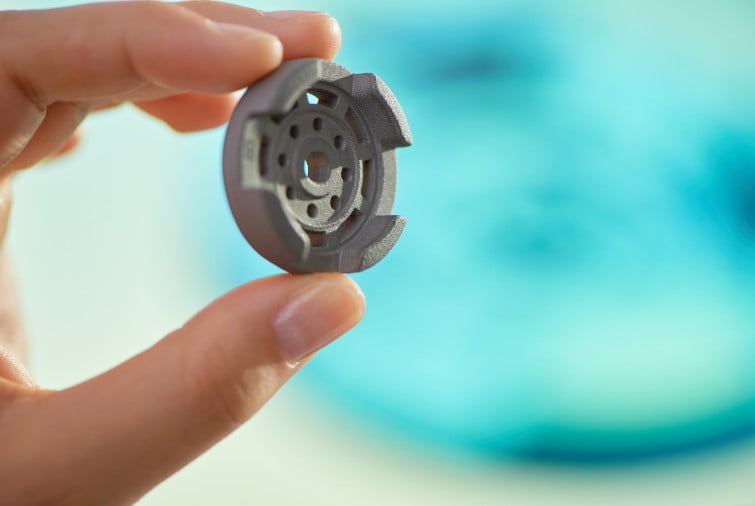

HP is the leader in 3D printing at scale with its line of Jet Fusion industrial printers. HP recognized early on that 3D printing was an emerging market that could take the leading technology the firm had developed for traditional printing and turn that into a 3D printing advantage. First, HP started with a solution that would create plastic prototypes, then moved quickly to solutions that could turn out production-ready finished parts which have already revolutionized the automotive and prosthetics industries.

This month, HP announced its Metal Jet Fusion 5200 Series of Industrial 3D printers which will further advance HP’s leadership into production-ready, 3D printed additive manufacturing.

HP’s 3D Printers

HP’s 3D printers reside in the middle ground between prototyping (where parts are made one-off and where the 3D market is very crowded) and high-volume manufacturing (where 3D printers aren’t yet competitive with traditional manufacturing methods).

HP’s solutions work for relatively short runs where there is a need for a lot of variety in a related product line, reducing the volumes of the unique parts down to something HP’s solutions can handle. Customized trim, prosthetics, and production runs of under 100K units are the sweet spots for HP’s technology, and where it has financial advantages over other solutions like CNC machines which are limited to far lower values and have far higher production costs.

At some point, you can imagine these machines being placed in distribution centers or even in high-volume stores to provide a greater degree of product variability and customization than would typically be possible, or in medical labs making custom prosthetics that would be competitively priced with generic products while providing a far better user fit.

Metal Jet S100

Plastics have severe temperature and durability limits. For instance, you can’t use them in gas motors or electric engines. They can also degrade in the sun and they lack the rigidity of metals so perform poorly where such rigidity is required. Metals have far greater utility in areas where there is a lot of heat, where there is a significantly greater load, and where you need something to stand up for long periods of time in the hot sunlight.

HP’s Metal Jet S100 initially uses stainless steel which is good for cosmetic parts but limited, for good reason, in markets like transportation due to it being exceptionally brittle for a metal. However, it holds up well in or near the water (with limited corrosion and no rust), where higher strength is needed, and where the appearance of the metal is more important than its strength.

But there is nothing that limits HP’s choice of metals. Once this printer has been delivered in volume, I expect HP will embrace other metals with titanium being, in effect, the killer app.

While not ideal, stainless steel can be used for weaponry parts and could, with the proper help and hardening, be used to support troops and troop equipment behind battlefield lines, turning that location into a critical logistics source for repair parts.

In addition, the combination of HP’s older plastic 3D printers with its current metal 3D printers suggests a “better together” strategy that could blend metal and plastic parts and come close to a much more comprehensive and complex multi-printer experience. And the resulting metal and plastic parts could be, depending on design, blended together to create ever more complex and interesting products or sub-systems.

Wrapping up: The future of automated additive manufacturing

Used right, 3D printers could provide a level of customization for our purchases, particularly in the automotive and prosthetics industries, the like of which we have never seen before. With 3D printers, we should get far more customizable products and far more customizable options over time. We are already getting better prosthetics, and even the aftermarket will benefit as parts can be profitably made for things that have been out of production for years and just need a little bit of a refresh.

It also promises to be a sustainable revolution when 3D printers become more prevalent because not only can existing products remain in service longer with better availability of repair parts, but increasingly, 3D-printed products will be easier to recycle so that their materials can be used for future products more easily when discarded.

We are at the front end of a manufacturing revolution. Once it’s over, manufacturing will never be the same.

- CES 2026: The Year AI Got Real, Lenovo Owned the Vision, and Memory Prices Broke the Bank - January 13, 2026

- The Gerstner Legacy: How Marketing Saved IBM and Why Tech Keeps Forgetting It - January 2, 2026

- The Silicon Manhattan Project: China’s Atomic Gamble for AI Supremacy - December 28, 2025