In many maker spaces, laser cutting and 3D printing are used together in order to create impressive, detailed items and works of art. However, outside the world of makers, many people aren’t sure how the two are different from each other. It’s true that they have some similarities, but laser cutting and 3D printing are actually very different technologies.

In many maker spaces, laser cutting and 3D printing are used together in order to create impressive, detailed items and works of art. However, outside the world of makers, many people aren’t sure how the two are different from each other. It’s true that they have some similarities, but laser cutting and 3D printing are actually very different technologies.

Defining the Terms

The first step to explaining the difference between laser cutting and 3D printing is to define the terms.

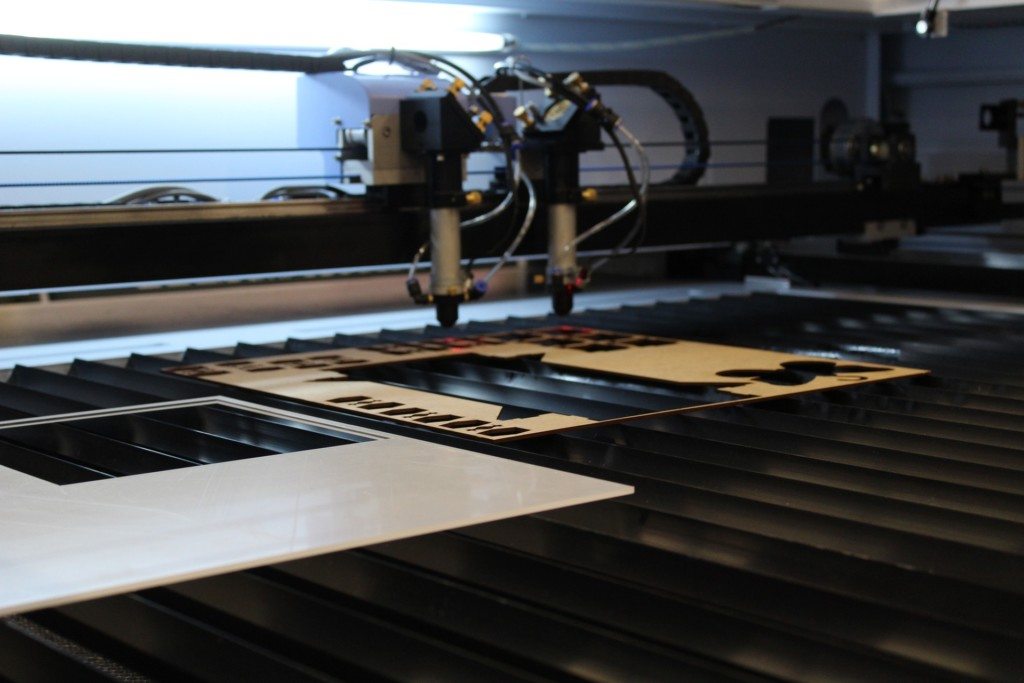

Laser cutting is a subtractive process; that is, it cuts material way from the source in a designed shape or pattern using either a 3D or a tube laser. These lasers are fast and extremely accurate, making it possible to make intricate, precise cuts quickly and easily. Laser cutters can cut a wide range of materials, often different metals, but it can also be used for fabrics, wood, and composite materials. While laser cutting can help speed the prototyping process, it’s usually limited to creating parts that must be welded or otherwise finished to create both prototypes and finished products.

3D printing, on the other hand, is an additive process, and thus completely different from laser cutting. To use a 3D printer, you must first create a 3D model of the item that you wish to “print.” Then the printer “adds” layer upon layer of materials, typically glue and resin, to build a 3D, real-life version of the item. Nothing is ever cut, but rather the item is built up via thin layers.

The Primary Differences Between Cutting and Printing

Both laser cutting and printing, by merit of their speed, are ideal for rapid prototyping processes. However, laser cutting tends has a slight advantage in this area, as it can be used for manufacturing as well as prototyping. 3D printing, on the other hand, is generally not used for items that are meant to be finished products or sold, although there are some industries where engineers are experimenting with different materials for more permanent construction. In many cases, 3D printing is used either to model a design to identify potential flaws and improvements before it’s used in manufacturing, or to create molds for the production of specific items. This is in large part because of the tools that 3D printers use; unlike a laser cutter, which can cut metal, 3D printers use less durable materials.

In fact, cost is one of the major factors that lead many makers to choose a laser cutter over a 3D printer. While certain materials can be pricey, the resin used in 3D printing is still quite pricey; a less expensive glued powder is typically only durable enough for temporary models. Consider the story of one maker. In developing a game, the original pieces were made of cardboard. However, for later editions, the maker wanted something a bit more upscale. He tried 3D printing the pieces, but was disappointed in how long it took to create one piece and the cost of the piece: 90 minutes and $45 for one piece. The piece was also a single color, which wasn’t what he had in mind. Using a laser cutter, the maker was able to quickly produce multiple wooden pieces for the game in just 30 seconds, for about the same cost. As a bonus, because the pieces were wood, they could be customized with paint, giving the maker the flexibility he wanted.

In fact, cost is one of the major factors that lead many makers to choose a laser cutter over a 3D printer. While certain materials can be pricey, the resin used in 3D printing is still quite pricey; a less expensive glued powder is typically only durable enough for temporary models. Consider the story of one maker. In developing a game, the original pieces were made of cardboard. However, for later editions, the maker wanted something a bit more upscale. He tried 3D printing the pieces, but was disappointed in how long it took to create one piece and the cost of the piece: 90 minutes and $45 for one piece. The piece was also a single color, which wasn’t what he had in mind. Using a laser cutter, the maker was able to quickly produce multiple wooden pieces for the game in just 30 seconds, for about the same cost. As a bonus, because the pieces were wood, they could be customized with paint, giving the maker the flexibility he wanted.

That being said, professional-grade laser cutters are expensive, but given their ability to cut multiple materials, cut larger sizes, and be used to create finished products — or parts for finished products — they do have some advantages over 3D printers. Not to mention, many makers are finding that 3D printing isn’t ideal for their needs, and that other ways of constructing things, such as laser cutting, are preferable. That’s not to say that 3D printing doesn’t have its applications, but laser cutting isn’t something that should be overlooked.

At the end of the day, while 3D printing and laser cutting do share some features, mainly the ability to create three-dimensional objects and speed up the prototyping process, they really are different technologies with different applications, strengths, and weaknesses. For that reason, it’s advantageous to any maker space to offer both options.

- SEO Misinformation – and How to Avoid It - September 26, 2019

- Cyberthreats Your Business Isn’t Prepared For - March 12, 2019

- Why You Shouldn’t Go DIY With Home Security - January 27, 2019

It’s interesting to learn that laser cutting can make precise shapes and cuts using a 3D or tube laser at a lower cost. I’ve witnessed how lasers perform its function and it’s so fast that it can finish the task (depending on how complicated it is) in a matter of seconds. I can only imagine how efficient it can get when being used in the manufacturing business, such as wood and fabric. If I were a manufacturer, I will certainly be investing in these to accomplish my required supplies that I’ll be looking to deploy for my suppliers.